Cold temperatures put stress on lintels because building materials contract, moisture trapped in masonry freezes and expands, and steel components corrode more quickly in winter. Over time, this combination weakens the load-bearing support above doors and windows, leading to cracks, shifting masonry, and structural movement if the issue is not addressed early.

Lintels are horizontal structural elements installed above openings such as doors and windows to support the weight of the surrounding wall. In cold weather, repeated freeze-thaw cycles, temperature fluctuations, and moisture intrusion place additional pressure on these components, especially in residential and commercial buildings where steel and concrete lintels are commonly used.

This article explains how winter conditions affect lintel stability, the warning signs that indicate cold-weather damage, and the preventive steps property owners can take to reduce structural stress before minor issues turn into costly repairs.

What Is a Lintel and Why Is It Structurally Important

A lintel is a horizontal structural support installed above openings, such as doors and windows, to carry the weight of the wall above. It redirects the load away from the opening and transfers it safely into the surrounding masonry, helping the structure remain stable over time.

Lintels are commonly made from steel, concrete, or stone, depending on the building type. Their structural role includes:

- Distributing structural loads so that pressure does not concentrate above doors and windows.

- Maintaining the shape of openings by supporting load-bearing walls above them.

- Supporting architectural design without compromising structural safety.

- Protecting the surrounding masonry from cracking caused by uneven weight transfer.

When a lintel begins to fail, it can no longer perform these functions effectively. This often results in visible and hidden issues such as:

- Cracks forming above doors or windows due to uneven load distribution.

- Sagging or bulging masonry around the opening.

- Sticking or misaligned doors and windows caused by structural movement.

- Water intrusion occurs as gaps develop between the lintel and masonry.

How Cold Temperatures Affect Lintels’ Stability

Cold weather affects lintel stability by causing material movement, trapping moisture within masonry, and increasing stress on load-bearing openings. During winter, repeated temperature changes and moisture exposure weaken the structural performance of lintels in both residential and commercial buildings.

1. Temperature-Driven Material Movement

Lintels and surrounding masonry expand and contract at different rates as temperatures fluctuate. In cold conditions, this constant movement creates internal stress at the joint between the lintel and the wall.

- Materials contract when temperatures drop, tightening pressure around the opening.

- Expansion occurs when temperatures rise, reversing the stress direction.

- Repeated cycles weaken the bond between the lintel and masonry over time.

Cold temperatures affect other structural elements in similar ways, especially around openings. You can also read How winter weather damages window sills and weakens their support over time.

2. Freezing and Thawing of Masonry Around Lintels

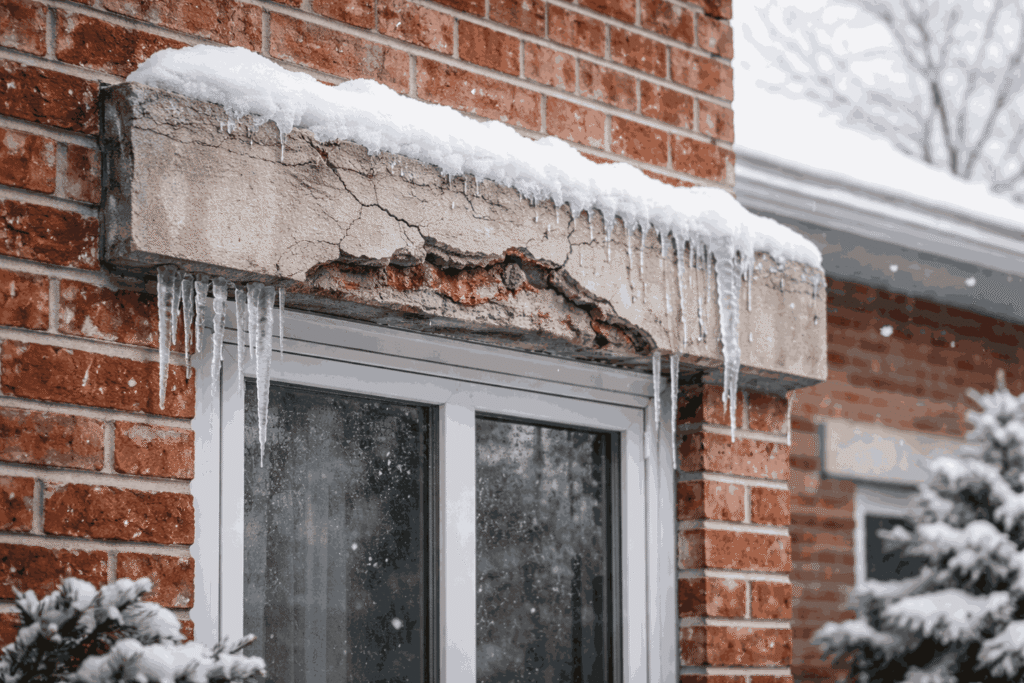

Freeze-thaw cycles are one of the most damaging winter conditions for lintels. Moisture enters small cracks near the opening and expands when it freezes, gradually forcing the masonry apart.

- Water seeps into porous brick or mortar near the lintel.

- Freezing temperatures cause the trapped moisture to expand.

- Each cycle widens cracks and reduces masonry support around the lintel.

3. Added Structural Stress From Snow and Ice Buildup

Snow and ice accumulation increase the load placed on exterior walls and structural openings. This added weight places extra pressure on lintels that are already stressed by temperature changes.

- Snow buildup increases vertical load on exterior masonry.

- Ice formation concentrates stress around doors and windows.

- Frozen moisture remains trapped, preventing proper drainage.

4. Cold-Induced Rusting of Steel Lintels

Steel lintels are particularly vulnerable in winter due to constant exposure to moisture. As steel corrodes, it expands, pushing against surrounding masonry and causing displacement.

- Melted snow and ice seep into masonry joints.

- Condensation forms on cold steel surfaces.

- Poor drainage allows moisture to remain in contact with the lintel.

5. Reduced Material Flexibility in Low Temperatures

Cold weather makes many construction materials less flexible, increasing the risk of cracking and structural movement around lintels.

- Mortar becomes stiff and loses its ability to absorb movement.

- Older steel becomes more prone to brittleness.

- Concrete may develop fine cracks under repeated stress.

Warning Signs That Cold Weather Is Damaging Your Lintels

Structural stress caused by winter conditions rarely appears all at once. Instead, it develops gradually as moisture, freezing temperatures, and material movement place pressure on lintels around doors and windows. Over time, this stress becomes visible through clear warning signs.

- Horizontal or stair-step cracks above openings indicate uneven load distribution as the lintel weakens.

- Rust stains on brickwork often point to corrosion inside steel lintels.

- Bulging or displaced masonry, caused by internal expansion from rust or trapped frozen moisture.

- Doors and windows are becoming difficult to open, a sign of structural movement around the opening.

- Gaps are forming between the lintel and the surrounding masonry, increasing the risk of water intrusion.

How to Reduce Winter-Related Damage to Lintels

Preventing lintel damage during winter largely depends on controlling moisture and limiting structural movement before freezing temperatures set in. Simple maintenance steps taken early can significantly reduce stress on lintels and help protect both residential and commercial structures from long-term damage.

- Seal existing cracks before winter, as even small openings allow moisture to enter and expand during freeze-thaw cycles.

- Install proper flashing above lintels, directing water away from openings and preventing moisture buildup inside masonry.

- Repair deteriorated mortar joints promptly to restore structural support and limit water penetration.

- Apply protective coatings to exposed steel lintels to reduce the risk of winter moisture-induced corrosion.

- Schedule routine building inspections, especially before and after winter, to identify early signs of lintel stress.

Many property owners also wonder whether repairs can be carried out safely in winter, which is discussed in Can masonry work be done in the winter?

When Lintel Damage Requires Professional Repair

Some lintel issues can be managed through routine maintenance, but sure warning signs indicate deeper structural problems that should not be ignored. When winter-related stress begins to compromise load-bearing performance, professional repair becomes necessary to maintain building safety.

- Progressive cracking around doors and windows indicates that the lintel is no longer distributing structural loads evenly.

- Visible rust expansion, where corroding steel lintels push against surrounding masonry and cause displacement.

- Structural movement around openings, leading to misaligned doors and windows or visible masonry shifting.

- Repeated winter-related damage suggests underlying moisture or structural issues that basic repairs cannot resolve.

Final Thoughts

A single issue rarely causes Lintel damage during winter. It usually develops through a combination of moisture intrusion, freeze-thaw cycles, and repeated material movement, which gradually weaken the load-bearing support above doors and windows. When left unaddressed, these small changes can lead to larger structural problems over time.

Identifying early warning signs and taking preventive steps before winter sets in is key to maintaining structural stability. Regular inspections and timely repairs help protect lintels, preserve surrounding masonry, and reduce the risk of long-term damage in both residential and commercial buildings.

Sardar Restoration Corp provides professional lintel repair and masonry services across NYC, including the Bronx, Manhattan, Brooklyn, Westchester, and Queens. Our team focuses on identifying underlying structural issues and applying long-lasting solutions suited to local building conditions.

For inspections or repairs, contact us at (+1) 917-355-8556, email sardarrestoration@gmail.com, or visit us at 2770 Fish Ave, Bronx, NY 10469, United States.

FAQs

Why do lintels crack more during cold weather?

Due to freeze-thaw damage, the lintel cracks more often in cold weather because the lintel and masonry contract, leading to moisture absorption in the cracks and their gradual widening.

Are steel lintels more affected by cold temperatures than concrete lintels?

Yes! Steel lintels are more affected by concrete in cold temperatures because constant moisture exposure leads to steel corrosion, which further cracks and displaces the framework.

How do freeze-thaw cycles damage lintels?

Freeze-thaw cycles occur when water enters small cracks around the lintel, freezes, and expands. Each cycle widens the cracks, weakening the masonry support and potentially causing the lintel to shift or lose its load-bearing capacity.

What are the early warning signs of lintel stress in winter?

The following are the early warning signs of lintel damage in winter, which should be addressed immediately to prevent costly repairs:

- Horizontal or stair-step cracks above windows or doors.

- Rust stains on brick or stone.

- Bulging or lifted masonry.

- Doors and windows are sticking or misaligned.

Do you offer lintel repair services?

Yes! Our window sills and lintels contractor in NYC Offers repairs, replacements, and installation services with a lasting guarantee of materials and artistry.

Can lintel damage get worse after winter ends?

Yes. Winter moisture that remains trapped in masonry can continue causing rust, cracking, and movement even after temperatures rise, leading to delayed structural damage.

Is lintel damage more common in older brick buildings?

Yes. Older buildings often have steel lintels with less corrosion protection, making them more vulnerable to freeze-thaw cycles and long-term moisture exposure.