Waterproofing is often treated as a finishing task, but in reality, it functions as a protective system for the entire structure. When done incorrectly, it allows moisture to penetrate walls, floors, and foundations, leading to leaks, internal damage, and long-term structural issues.

In residential and commercial buildings, especially in dense urban environments like NYC, waterproofing failures rarely happen overnight. They develop gradually due to overlooked details, incorrect methods, or decisions made during installation that compromise performance over time.

Understanding where waterproofing commonly goes wrong is the first step toward preventing costly repairs and recurring water damage.

- Ο Waterproofing failures are usually caused by human error, not product defects.

- Ο Small installation mistakes often lead to hidden moisture infiltration.

- Ο Cracks, joints, and drainage conditions directly affect waterproofing performance.

- Ο High-risk areas require targeted treatment, not surface-level coating.

- Ο Long-term protection depends on correct preparation, material choice, and system planning.

Why Waterproofing Fails Before Leaks Appear

Most waterproofing systems do not fail immediately after installation. In many cases, they appear intact as water slowly seeps through weak points beneath the surface. These failures often begin at locations that were either ignored, rushed, or misunderstood during planning or application.

Water follows the path of least resistance. When surfaces are not adequately prepared, materials are incompatible, or movement is not accounted for, moisture bypasses the waterproofing layer rather than penetrating it. Over time, pressure builds, materials deteriorate, and minor gaps turn into active leaks.

This is why identifying common waterproofing mistakes is critical. Each mistake may seem minor on its own, but together they create conditions where waterproofing systems lose effectiveness long before visible damage appears.

Improper Substrate Preparation Before Waterproofing

Improper substrate preparation is the most common reason waterproofing systems fail, even when high-quality materials are used. Waterproofing products are engineered to bond with stable, clean, and moisture-free surfaces. When this foundation is compromised, the entire system becomes vulnerable from the start.

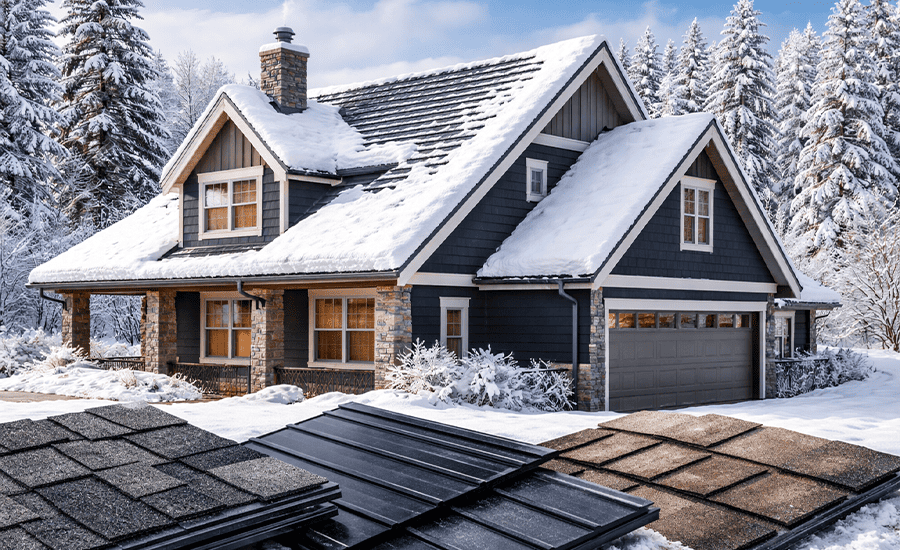

In real-world site conditions, surfaces may appear ready but still contain dust, residue, moisture, or micro-level deterioration. Applying waterproofing without correcting these issues prevents proper adhesion and allows moisture problems in homes during freezing weather to weaken the waterproofing system from beneath.

Common Preparation Mistakes

- Applying waterproofing over dusty, dirty, or uneven surfaces.

- Ignoring grease, oil, or chemical residues that block bonding.

- Sealing substrates while moisture is still present beneath the surface.

- Skipping crack repairs, patching, or surface levelling.

- Applying coatings on loose, flaking, or weakened concrete and masonry.

Why This Leads to Leaks

When waterproofing materials fail to bond correctly:

- Membranes detach or blister over time.

- Water travels behind the waterproofing layer instead of being blocked.

- Small adhesion failures expand into widespread moisture intrusion.

In older buildings and high-moisture zones such as basements and parapet walls, this issue becomes more severe. Without proper surface assessment and preparation, waterproofing functions as a surface cover rather than a protective barrier.

Inappropriate Waterproofing Material Selection

Choosing the wrong waterproofing material is a critical mistake that often leads to early system failure, even when installation is done correctly. Waterproofing products are designed for specific conditions, surfaces, and exposure levels. When material selection does not match the site requirements, performance declines rapidly.

In many residential and commercial projects, materials are chosen based on availability or cost rather than movement tolerance, UV exposure, moisture pressure, and environmental conditions. This mismatch creates stress within the system, especially when materials fail under cold air impact on waterproofing performance.

Common Material Selection Mistakes

- Using interior-grade waterproofing products in exterior environments.

- Applying rigid coatings on surfaces that experience regular movement.

- Using non-UV-resistant materials in exposed areas.

- Installing roof sealants for foundations or below-grade applications.

- Selecting products based solely on price instead of performance suitability.

How Incorrect Materials Cause Leaks

When materials are incompatible with the surface or environment:

- Coatings crack due to temperature changes and structural movement.

- UV exposure causes premature degradation.

- Waterproofing layers lose elasticity and protective integrity.

- Water penetrates through micro-cracks and weakened sections.

In climates like NYC, where buildings face seasonal expansion, freeze-thaw cycles, and prolonged moisture exposure, material compatibility is essential. Waterproofing must function as a flexible, durable system rather than a rigid surface layer to provide long-term protection.

Ignoring Existing Cracks and Structural Movement

Applying waterproofing over existing cracks or structural damage is one of the fastest ways to cause system failure. Waterproofing materials are designed to resist moisture, not to correct structural weaknesses. When cracks or movement are ignored, water eventually bypasses the waterproofing layer through these vulnerable points.

In many buildings, cracks may appear minor on the surface but indicate deeper issues such as settlement, thermal expansion, or material fatigue. Coating over these areas without proper repair traps stress beneath the waterproofing, as mortar cracks faster in cold weather due to repeated structural movement.

Commonly Overlooked Structural Issues:

- Hairline foundation and masonry cracks.

- Settlement or shrinkage-related cracking.

- Expansion joints without flexible sealants.

- Structural movement caused by temperature changes.

- Hidden separation at wall-to-floor junctions.

How Cracks Turn Into Active Leaks

When structural issues are left untreated:

- Cracks widen with seasonal movement.

- Waterproofing layers stretch beyond their tolerance.

- Membranes split or lose adhesion.

- Water follows these paths into interior spaces.

In older residential and commercial buildings, especially those with rigid construction elements, ignoring movement allowances significantly increases the risk of recurring leaks. Effective waterproofing begins with stabilizing and sealing structural vulnerabilities before protective layers are applied.

Incorrect Waterproofing Installation Techniques

Even the right waterproofing material can fail when it is installed incorrectly. Waterproofing systems rely on precise application methods, controlled thickness, and proper curing conditions to perform as intended. Deviations during installation weaken the system and create vulnerable points where water can penetrate.

Installation errors often occur when application guidelines are rushed, weather conditions are ignored, or required preparation steps are skipped. These mistakes may not be immediately visible, but they gradually reduce the waterproofing system’s ability to resist moisture.

Common Installation Errors

- Applying waterproofing layers too thin or unevenly.

- Skipping required primer or bonding coats.

- Ignoring manufacturer-recommended curing times.

- Applying materials during unsuitable weather conditions.

- Failing to maintain consistent coverage at edges and transitions.

Why Installation Errors Lead to Leaks

When waterproofing is improperly applied:

- Moisture barriers remain incomplete.

- Weak spots form within the system.

- Water exploits inconsistencies in thickness and adhesion.

- Long-term durability is significantly reduced.

In environments with fluctuating temperatures and seasonal moisture exposure, such as NYC, improper installation accelerates material breakdown. A professional application ensures that waterproofing performs as a continuous protective system rather than a patchwork of coatings.

Many property owners also question whether masonry-related work should be delayed due to cold conditions, but understanding Winter masonry work feasibility and limitations helps avoid unnecessary postponements and poor decisions.

Inadequate Drainage and Water Management

Waterproofing systems are designed to resist moisture, not to handle standing or trapped water indefinitely. When drainage is poor or improperly planned, excessive water pressure builds up against waterproofed surfaces, forcing moisture to find weak points within the system.

In many residential and commercial buildings, drainage is treated as a secondary concern. However, without proper water flow management, even well-installed waterproofing layers become overwhelmed over time.

Common Drainage-Related Mistakes

- Clogged, damaged, or missing drains.

- Improper surface slopes directing water toward the building.

- Blocked or non-functional weep holes.

- Inadequate placement of downspouts.

- Poor runoff management on roofs, balconies, and terraces.

How Poor Drainage Causes Leaks

When water is unable to drain properly:

- Hydrostatic pressure increases and leads to basement leaks during winter months.

- Water is forced through joints, seams, and minor defects.

- Waterproofing layers experience constant stress.

- Small vulnerabilities turn into persistent leakage points.

In dense urban settings like NYC, where flat roofs, balconies, and below-grade spaces are common, drainage failures accelerate the breakdown of waterproofing. Effective waterproofing must work in conjunction with a properly designed drainage system to ensure long-term moisture control.

Failure to Treat High-Risk Water-Prone Areas

One of the most overlooked causes of waterproofing failure is neglecting areas that are naturally more vulnerable to water intrusion. These locations experience constant exposure and deterioration linked to cold weather masonry problems and repairs in vulnerable exterior areas.

In many projects, waterproofing is applied evenly across surfaces without giving additional attention to transitions, edges, and penetrations. As a result, water enters through points where stress and exposure are highest.

Commonly Overlooked High-Risk Areas

- Roof edges, flashings, and penetrations.

- Balconies and terrace junctions.

- Window and door perimeters.

- Bathroom floors and wet wall areas.

- Basement wall-to-floor connections.

Why These Areas Develop Leaks

When high-risk zones are not treated properly:

- Waterproofing layers thin out at edges and transitions.

- Movement causes cracking at junction points.

- Water concentrates around penetrations and seams.

- Moisture bypasses primary waterproofing layers.

In residential and commercial buildings, these zones require reinforced membranes, flexible detailing, and careful sealing to maintain continuity. Ignoring them turns otherwise effective waterproofing systems into vulnerable assemblies prone to localized leaks and interior damage.

Poor Joint and Sealant Application

Joints are natural points of movement within a structure and are among the most common entry points for water. When joints are sealed incorrectly or overlooked, waterproofing systems lose continuity, allowing moisture to bypass protective layers.

In many residential and commercial projects, sealants are treated as finishing details rather than as critical components of the waterproofing system. Using the wrong sealant type or misapplying it reduces flexibility and compromises long-term performance.

Common Joint Sealing Mistakes

- Using rigid sealants instead of flexible, movement-tolerant products.

- Skipping sealing around pipes, conduits, and service penetrations.

- Ignoring expansion and control joints.

- Applying sealants without proper surface preparation.

- Inconsistent sealant depth or poor adhesion.

How Joint Failures Lead to Leaks

When joints are not sealed correctly:

- Sealants crack or separate due to structural movement.

- Water bypasses membranes at transition points.

- Small gaps allow continuous moisture infiltration.

- Repeated exposure leads to interior damage and material deterioration.

In buildings exposed to seasonal temperature changes and structural movement, joint detailing must allow flexibility while maintaining a watertight seal. Proper joint treatment ensures that waterproofing systems remain effective across all connected surfaces.

Best Practices To Prevent Waterproofing Failures

Preventing waterproofing failure is not about using more material, but about applying the right approach at the right stage. Long-lasting waterproofing depends on system planning, surface readiness, and ongoing oversight rather than isolated fixes.

1. Assess the Surface Before Any Application

Before waterproofing begins, surfaces should be thoroughly inspected for moisture, cracks, instability, and contamination. Waterproofing should be applied only after the substrate is clean, dry, structurally sound, and properly repaired.

2. Select Materials Based on Conditions, Not Cost

Waterproofing materials must be chosen based on exposure level, surface movement, UV contact, and moisture pressure. Compatibility between the substrate, environment, and waterproofing system is essential for durability.

3. Address Structural Issues First

Cracks, movement joints, and weak structural areas must be repaired or stabilized before waterproofing is applied. Waterproofing should protect a stable structure, not attempt to compensate for unresolved damage.

4. Follow Proper Installation Standards

Correct layer thickness, uniform coverage, primer use, and curing time are critical. Installation should always follow the manufacturer’s specifications and account for weather conditions during application.

5. Design for Proper Drainage

Adequate drainage reduces pressure on waterproofed surfaces. Slopes, drains, and water exit points must work together to prevent water buildup around walls, roofs, and foundations.

6. Reinforce High-Risk Areas

Edges, joints, penetrations, and transitions should receive additional attention through reinforced membranes, flexible sealants, and detailed sealing methods.

7. Schedule Regular Inspections and Maintenance

Waterproofing systems should be inspected at least annually and after severe weather events. Early detection of wear or minor failure helps prevent significant structural damage and costly repairs.

Choosing the right professional plays a key role in long-term performance, and knowing How to evaluate and hire a qualified masonry contractor reduces the risk of improper installation and recurring issues.

Final Thoughts

A single issue rarely causes waterproofing failures; they occur when preparation, material selection, installation, and detailing are not treated as a complete system. Addressing these factors early and following a structured, professional approach helps prevent recurring leaks, reduces long-term repair costs, and protects the integrity of residential and commercial buildings, particularly in demanding urban environments like NYC.

Sardar Restoration Corp supports residential and commercial properties across NYC, including the Bronx, Manhattan, Brooklyn, Westchester, and Queens. Our work focuses on addressing real site conditions, seasonal moisture challenges, and building-specific vulnerabilities to ensure waterproofing systems perform reliably over time. Service availability can be reviewed based on your location to provide the right solution for your property.

For property assessments or waterproofing-related concerns, you can reach our team at (+1) 917-355-8556, email sardarrestoration@gmail.com, or visit 2770 Fish Ave, Bronx, NY 10469, United States.

FAQs

What is the most common waterproofing mistake that causes leaks?

The most common waterproofing mistake is poor surface preparation. When waterproofing materials are applied to dirty, damp, or damaged surfaces, they do not adhere well, leading to the wall peeling, cracking, and leaking water.

Can waterproofing fail even with high-quality materials?

Yes. It may fail even with the best-quality materials if it is not applied correctly. This is a very delicate process, and every detail must be carefully checked. The quality of applying waterproofing is more crucial than the products used.

Is waterproofing enough to stop leaks if there are cracks?

No. Waterproofing alone is not enough to prevent leaks if there are cracks or structural problems in the walls; these should be fixed before waterproofing. Cracks need to be sealed or repaired adequately before waterproofing to ensure long-term effectiveness.

Why does poor drainage cause waterproofing failure?

Poor drainage usually leads to waterproofing failures, allowing water to accumulate and exert pressure on walls, foundations, and roofs. This pressure forces water through weak points in the waterproofing, which causes leaks.

Which areas of a home are most prone to waterproofing mistakes?

The following are the areas most prone to waterproofing

- Basements and foundations

- Roof edges and penetrations

- Balconies and terraces

- Bathrooms and wet areas

- Window and door perimeters

These locations need extra care and timely inspections to ensure the well-being of your property.

Can waterproofing fail even without visible leaks or damage?

Yes. Waterproofing can deteriorate beneath the surface due to poor adhesion or trapped moisture, allowing water to spread before any visible signs appear.

Is partial waterproofing effective, or does the entire area need treatment?

Partial waterproofing often redirects water toward untreated sections, increasing pressure and causing recurring leaks over time.

How often should waterproofing be inspected or maintained?

One should have their property inspected at least once a year, and after severe weather events when damage to the walls has occurred. Regular maintenance detects minor issues earlier, helping prevent more serious damage and costly repairs.