New York City faces the most challenging weather conditions that badly affect the fire escape of your residential and commercial property. It is essential to use the highest-quality, industry-approved materials for NYC fire escapes to ensure they function correctly in an emergency. Choosing high-quality materials is also necessary to keep your fire escapes protected from harsh weather conditions and to provide a long lifespan, durability, safety, and low maintenance costs. Different types of fire escapes have different evacuation and load-bearing capacities. So make sure to install a fire escape made for NYC-appropriate weather conditions.

In this blog, we’ll break down the types of materials best for NYC weather, their advantages and disadvantages, and maintenance guidelines.

How NYC’s Weather Puts Structures to the Test?

NYC weather has a profound impact on the metal or concrete fire escape, and it costs you heavy repairs, which leads to the following issues:

| Weather challenges | Influence on fire escape | Results |

|---|---|---|

| Cyclic freeze-thaw exposure | Water infiltration | Paint delamination & surface cracking |

| Frequent rain and high humidity stress | Surface saturation | Intensified metal oxidation |

| Salt and melt agents | Salt washes onto the lower area | Electrochemical corrosion |

| Sunlight and temperature stress | Metal expansion with coating degradation | Surface flaking & material deformation |

| Acid rain damage | Initiates a metal reaction | Tiny cavity corrosion & color change |

The Preferred Material for NYC Fire Escapes

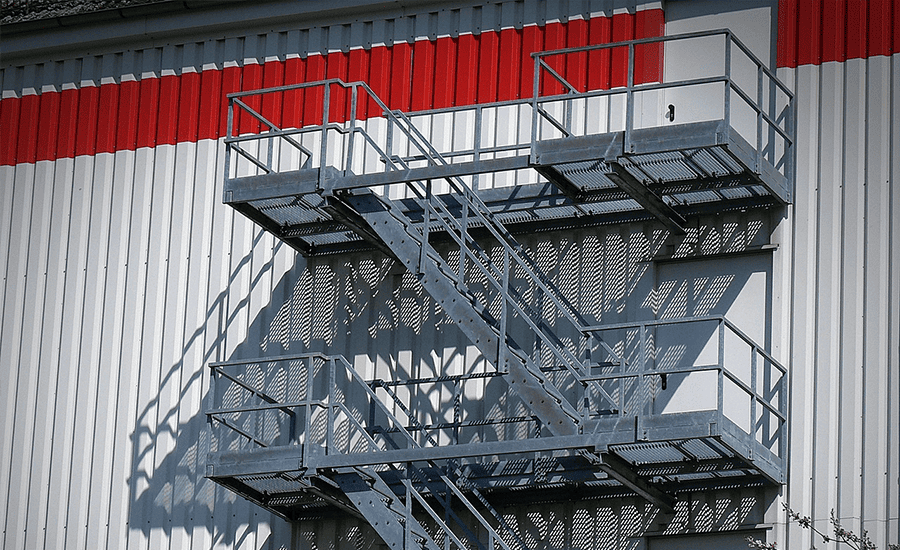

Galvanized steel is the most widely used and budget-friendly material for various types of fire escape construction in NYC. It shows value for its money and is made up by dipping the steel into zinc, which makes it rust-resistant for decades.

Favorable factors:

- Strong and reliable under heavy loads.

- The zinc layer protects against rust and moisture.

- Lower maintenance costs compared to painted steel.

- Excellent fire resistance and fully code-compliant.

- Easily repairable or replaceable sections.

Negative aspects:

- Zinc coating can wear down at joints or welds.

- Requires periodic inspection and touch-up painting.

- Salt exposure accelerates corrosion if the coating fails.

Excellent match for:

- Brownstones, multifamily apartments, commercial buildings.

- Owners seek a balance between cost, strength, and durability.

For insights into how metal fire escapes remain a top choice in specific boroughs, check out why are metal fire escapes popular in brooklyn?

Stainless Steel for Long-term Durability

Stainless steel is the best for historic fire escapes, as it is significantly strengthened, visually attractive, and doesn’t require rust-inhibiting coatings because it is already corrosion-resistant. This material can withstand salt-laden air, acid rain, and moisture in the environment.

Favorable factors:

- Immune to rust even when scratched.

- Low maintenance, no need for painting.

- Excellent for high-exposure locations (near streets or the coast).

- Modern, clean appearance suitable for new developments.

Negative aspects:

- Expensive to fabricate and install.

- Welding requires expertise and special tools.

- A shiny surface may not suit historic façades.

Excellent match for:

- High-end restorations or modern glass/steel buildings.

- Owners prioritize low maintenance and long lifespan.

You can explore more about the best materials for long-lasting fire escapes and how they perform under different NYC conditions.

Why Aluminum Is Ideal for Modern Fire Escape Construction?

Aluminum is the best material for modern fire escapes as it is rust-proof and has good weatherproofing capability, while it has less tensile durability than steel. It is ideal for light evacuation as it doesn’t carry heavy-weight.

Favorable factors:

- Will not rust or corrode.

- Lightweight, easier installation, and less stress on masonry walls.

- Great for retrofits and smaller residential structures.

- Reflective, modern appearance.

- Minimal upkeep with no painting required.

Negative aspects:

- Lower structural strength than steel.

- May deform under high heat (lower melting point).

- Requires thicker profiles for equal load capacity.

- Not ideal for very tall or heavily used fire escapes.

Excellent match for:

- Small residential or rooftop fire escapes.

- Projects requiring lightweight, low-maintenance solutions.

If you’re comparing materials, it’s helpful to know are aluminum fire escapes better than steel? to choose the right option for your property.

Types of Finishing Treatments

The following types of surface finishing treatment help you prevent corrosion and rusting in your steel framework. Let’s have a look at them:

| Surface treatment | Functional with | Shield from |

|---|---|---|

| Powder-fused finish | Steel / Aluminum | Scuffs & Sunlight exposure |

| Epoxy–polyurethane coating system | Galvanized steel | Humidity & de-icing salt |

| Galvanic protection primer | Welds & joints | Metal degradation |

| Aluminum treatment | Aluminum | Tarnishing |

Professional Contractor Advice for NYC Conditions

Before choosing any material, it’s important to understand how NYC’s unique climate and building standards affect performance. Here’s what professional contractors recommend for different property types and conditions across the city:

- Best choice for NYC apartment: Hot-galvanized steel is the best for fire escape in NYC apartments as it meets all the local codes and safety protocols.

- Works well in coastal neighborhoods: Stainless steel is the best in coastal areas, as these areas are exposed to too much salt-laden air, which causes rusting, but stainless steel prevents corrosion.

- Great for smaller-scale improvements: Aluminum is perfect for urban area buildings as it is resilient, rust-free, and has load-bearing capacity.

- To extend structural integrity and lifespan: Use galvanized and stainless steel with polyurethane coatings.

- Work only with qualified experts: Make sure to hire a licensed contractor who knows local NYC building codes and FDNY regulations.

To understand how building styles vary across NYC, read which fire escape type is most common in manhattan?

Conclusion

Selecting the right fire escape material for NYC isn’t just about cost; it’s about safety and longevity. With the city’s unpredictable weather, choosing durable materials like galvanized or stainless steel ensures your fire escape stays reliable for decades. Regular maintenance and expert installation can make all the difference in protecting both your building and the people inside.

Sardar Restoration Corp proudly serves every corner of NYC, including the Bronx, Manhattan, Brooklyn, Westchester, and Queens. Our services are designed to meet your specific needs, providing top-quality solutions wherever you are. Check our service areas to see how we can assist you in your location.

Contact us today at (+1) 917-355-8556 or sardarrestoration@gmail.com, or visit us at 2770 Fish Ave, Bronx, NY 10469, United States.

FAQs

Do you install new fire escapes in NYC?

Yes! Sardar Restoration Corp. Expertly handles all types of fire escape installations in NYC, using high-quality and industry-approved methods.

Can you repair or replace rusted metal steps?

Yes, we can! Sardar Restoration Corp. will repair and replace the rusted metal steps, but it depends on the severity of damage. We make sure to use rust-resistant sealants.

How often should I inspect my fire escape in NYC?

It’s recommended to inspect your fire escape at least once a year. Regular checks help identify rust, corrosion, or loose parts early, preventing costly repairs later.

What is the average lifespan of a well-maintained fire escape?

A properly maintained steel or stainless-steel fire escape can last 50 to 70 years, depending on exposure to elements and coating quality.

Which fire escape material lasts the longest in NYC?

Stainless steel grade 316 lasts the longest, over 70 years with minimal maintenance.

Do you offer maintenance or inspection services?

Yes! Sardar Restoration Corp. conducts yearly inspections and frequent maintenance services to keep your fire escape up to code and rust-free.